Tamron Lenses For Customized products:

Please select Customized products Lenses for Digital Cameras and Video Cameras you are interested in.

一、Customized products:Lenses for Digital Cameras and Video Cameras

Leveraging technologies and expertise cultivated over many years together with leading -edge technologies, TAMRON develops and supplies optical lens units that support image sensors with increasingly high pixel counts. Through our advanced, large-scale production system, we respond to all manner of customer needs in a flexible and speedy manner, and have earned a high degree of trust as a result.

二、Customized products:Built-in Lenses for Cameras (for Surveillance Cameras,IP/CCTV Cameras,etc.)

TAMRON has a full line up of lenses for CCTV/ IP camera manufactures and they may be used incorporating them into cameras.Please contact us about each models.

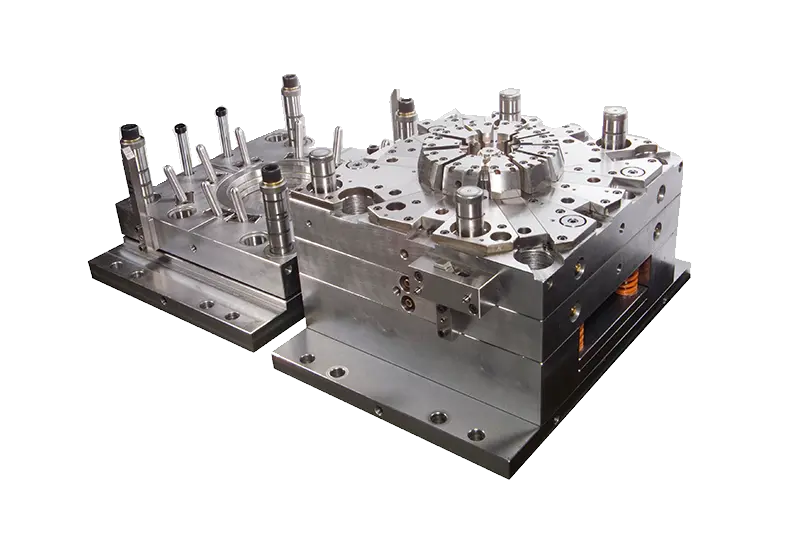

三、Customized products:High-Precision Molds / Injection-molded parts&components

1、High-precision molding dies into micron order

TAMRON is committed to meeting diversifying market needs and developing and manufacturing outstanding products. The company owns facilities and equipment for the design and production of high-precision mold, where it manufactures a range of precision equipment and optical-equipment parts. TAMRON is also dedicating resources to the introduction of next-generation injection-mold production equipment, which will further strengthen its development capabilities and dramatically reduce the lead time required for die production.

With our high-end three-dimensional CAD/CAM and ultra-precision machining equipment, we can start design, production, and testing in a short time. We provide high-quality molds that meet customer requirements and specifications by combining micron-level mold accuracy with years of mass production expertise in optical components.

2、Complete streamline from molding die design to injection molding process

TAMRON has gained steady experience over decades in production of key components with plastic high-precision injection molded materials for precision equipment as well as optical products. From molding die design, modeling simulation, to production, the entire process is performed under full supervision of our experienced engineers, fully committed to delivering parts and components fully compliant with spec requirements.

TAMRON has gained steady experience over decades in production of key components with plastic high-precision injection molded materials for precision equipment as well as optical products. From molding die design, modeling simulation, to production, the entire process is performed under full supervision of our experienced engineers, fully committed to delivering parts and components fully compliant with spec requirements.

Tamron begins by thoroughly understanding your unique requirements, ensuring lenses are developed exclusively for your application through comprehensive consultation.

We define the technical specifications and integrate your application conditions, such as working distance and wavelength, right from the start to create an optimized solution.

Our engineers provide design proposals with maximum flexibility, offering tailored solutions like downsizing casings, fixed apertures, or custom lens mounts.

We collaborate closely with you during the design review, maintaining transparent communication to ensure your expectations are met and exceeded.

Tamron’s engineers develop a customized solution by incorporating all relevant factors into the final product while ensuring flexibility for potential adjustments.

Tamron conducts a thorough evaluation of the prototype, providing continuous feedback to confirm it performs according to your expectations.

Upon approval, we proceed with mass production while maintaining flexibility for adjustments and ensuring seamless communication throughout the process.

Tamron offers ongoing support after production, ensuring your lenses perform optimally and continue to meet your project needs.