Di III Lenses Series For Mirrorless Cameras

Di III-A Lenses Series For Mirrorless Cameras

Di II Lenses Series For DSLR Cameras

Di Lenses Series For DSLR Cameras

Tamron Lenses Accessories

Tamron Lenses Softwares

Discontinued Lenses For Consumer

All Optical Lenses of Consumer

Network Surveillance Camera Lenses

FA and Machine Vision Lenses

Cameras Module

Automotive Lenses

Medical Devices

Precision Optical Devices

Discontinued Lenses For Business

All Optical Lenses of Business

Lenses for Digital Cameras

Lenses for Video Cameras

Built-in Lenses for Cameras

Lenses for Surveillance Cameras

Lenses for IP/CCTV Cameras

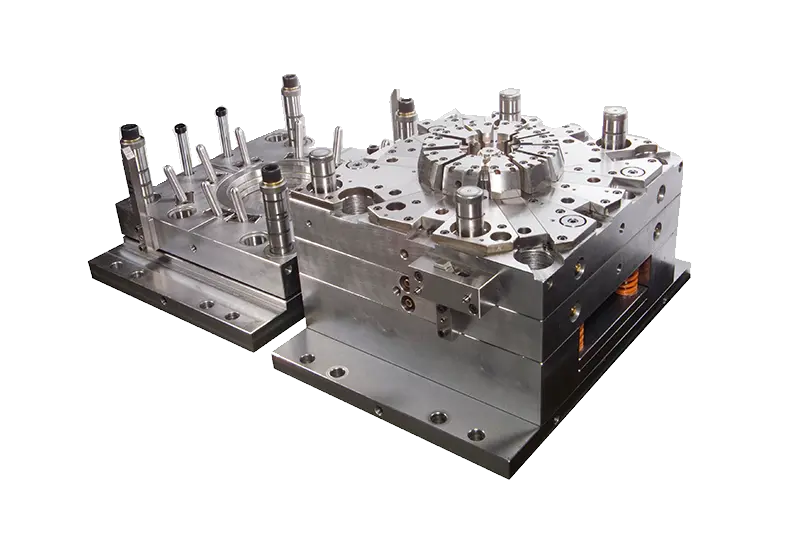

High-Precision Molds

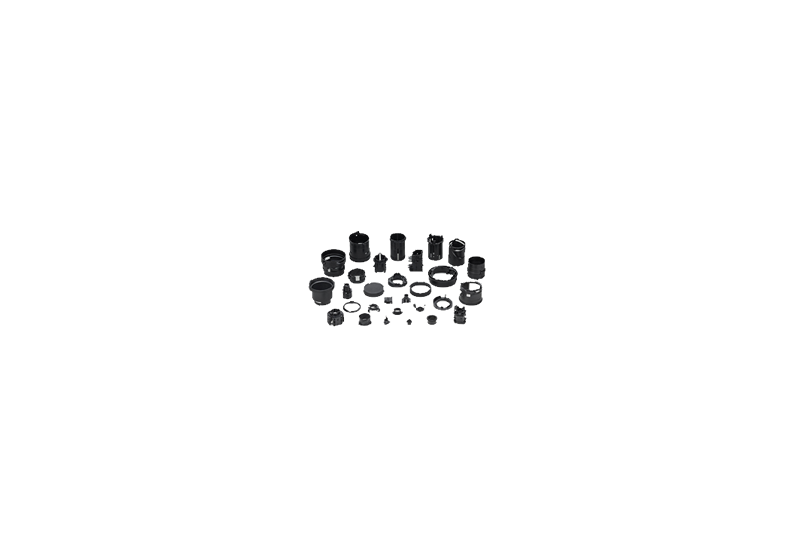

Injection-molded parts&components

All Optical Lenses of Customized

65mm Standard Telecentric Lenses

110mm Standard Telecentric Lenses

Non-Standard Telecentric Lenses

All Optical Lenses of Telecentric

About Tamron Company Information

Compatibility Lenses For Consumer

Corporate Social Responsibility

Tamron News & Events

English

English China

China